Owing to their similarities in build and design, most caravans and motorhomes share the same window manufacturers. Some of the most well-known brands are Dometic-Seitz, Heki and Fiamma.

However, certain older units (like mine) were fitted with windows made by a firm called Birkholz, which has long since ceased manufacturing them.

A quick look online forums highlights the problems this causes when you are trying to source any replacement windows (size incompatibility with current ranges) and spare parts for repairs.

Catch operation

In the main, Birkholz windows are quite robust and give long service, but those fitted to my van are of the three-point catch variety, using one central lever to operate all three catches simultaneously.

To do this, the lever drives a PVC strip in a channel which, in turn, activates the left and right catches.

As mentioned, the activation strip is made from PVC, and those of you who have an understanding of plastics will know that this material has an Achilles heel – it can become brittle over time.

Added to that, when PVC is cold, its malleability decreases, making it more likely to fracture.

This article describes the process of replacing the PVC with nylon, which has better thermal/ageing characteristics, coupled with excellent self-lubricating properties that enable it to slide more smoothly in the guide channel.

The nylon I’ve used here is Nylon 6, procured from a wholesaler (Amari Plastics, although others are available). I bought a complete minimum-order sheet (1m x 2m, 1.6mm thick) because trying to buy strip with the dimensions required is non-viable. Although buying the whole sheet cost me £42, it has enabled me to repair the five windows in my caravan at an average cost of £8 per window (with quite a bit left over, too). For this project, you will also need an aerosol can of PTFE.

Procedural tips

- The old PVC is highly likely to be brittle and might break even more when it is being removed. This is undesirable if it can be avoided, because the PVC has to be used as the pattern for cutting the new strip. Warming it with a heat gun or hairdryer will make things easier.

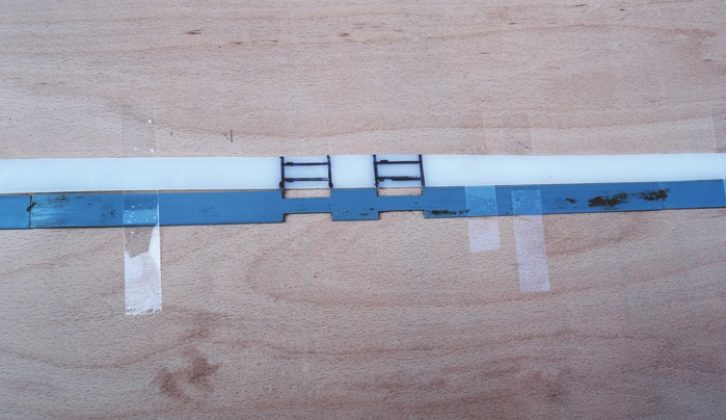

- When cutting the new strip of nylon, it is essential not to go oversize – it is very difficult to remove any excess from the side of the strip once cut.

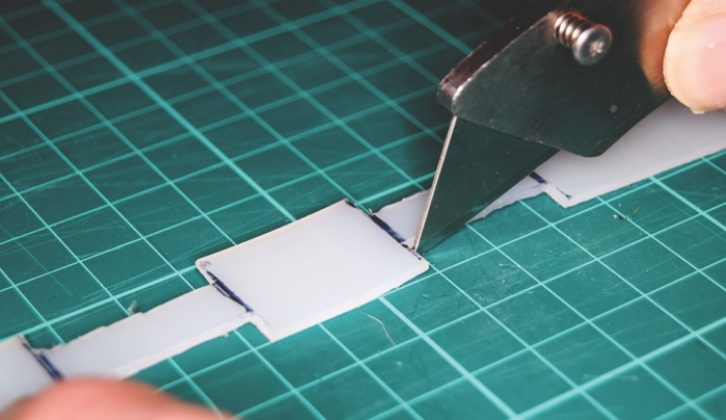

- Check that the new strip will operate smoothly in the channel before you move on to cutting the apertures.

Tools required

To complete this job, you’ll need a marking gauge, craft knife, shears/scissors, Torx screwdriver and various items from any conventional tool box.

A step-by-step guide

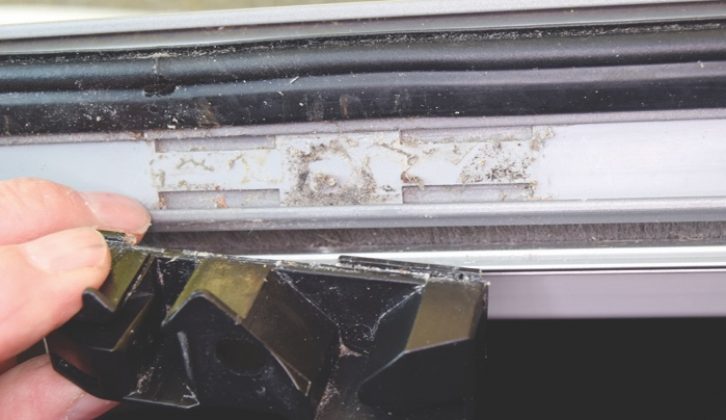

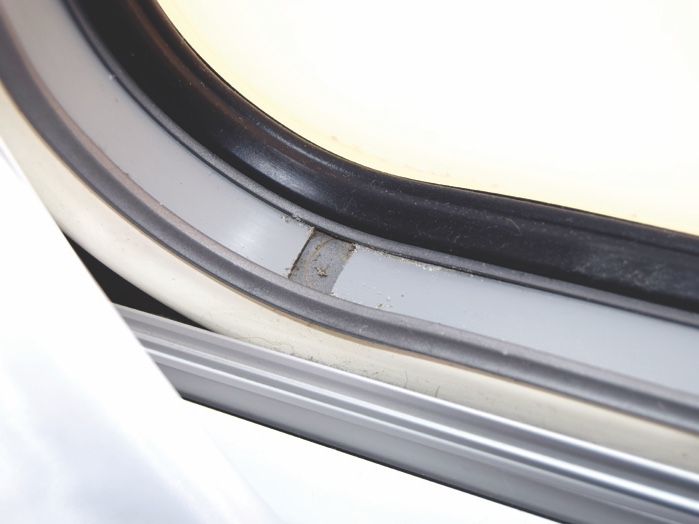

1. A split in this PVC strip has rendered the left-hand window catch inoperative.

2. Remove the end-stop screen from the left-hand side of the window frame.

3. Next, remove the window stay-bracket from the right-hand side of the frame.

4. The central sliding block is now ready to be removed from the window frame

5. Using two screwdrivers, push to release lugs, then pivot block out from runner.

6. Block removed, showing four recesses driving strip when catch is operated.

7. Widened section of track on left-hand side to facilitate withdrawal of strip.

8. Damaged PVC strip is then removed via the widened section of the track.

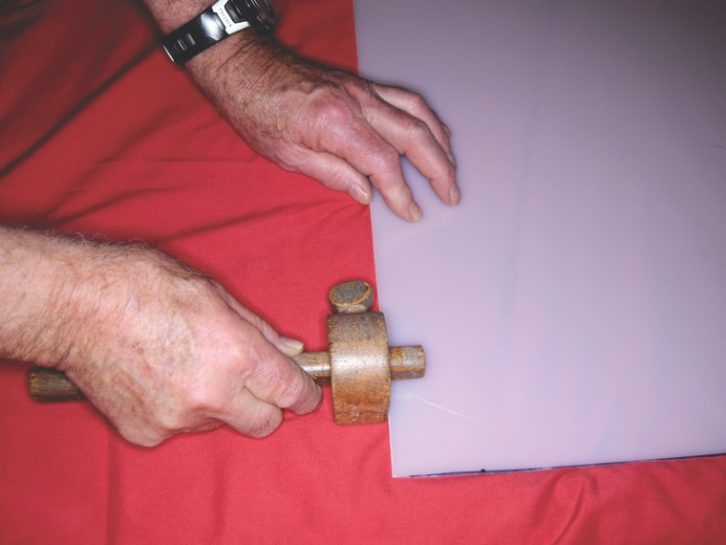

9. Set marking gauge to the required width (17mm in this example).

10. Next, carefully mark up the edge of the nylon sheet before cutting.

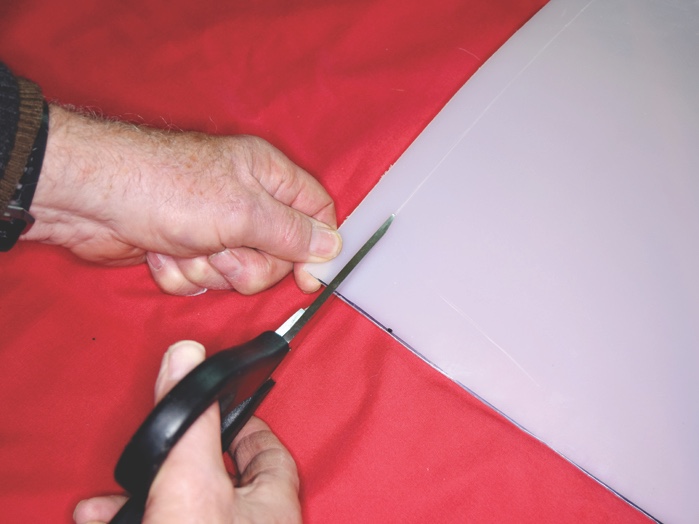

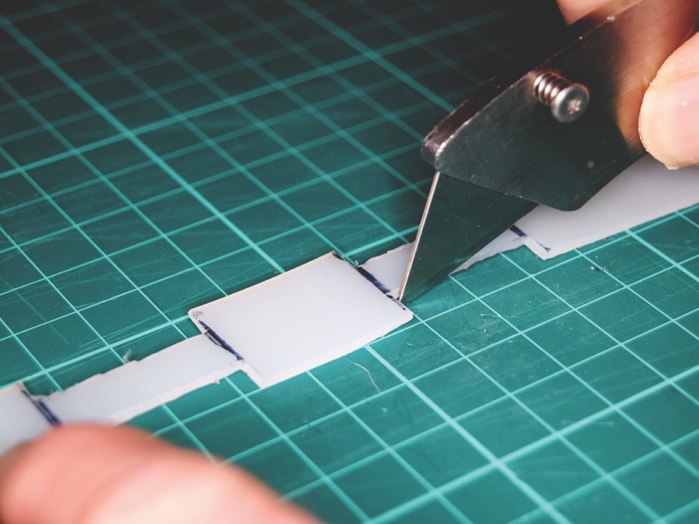

11. Using sharp scissors or shears, cut along the marked line

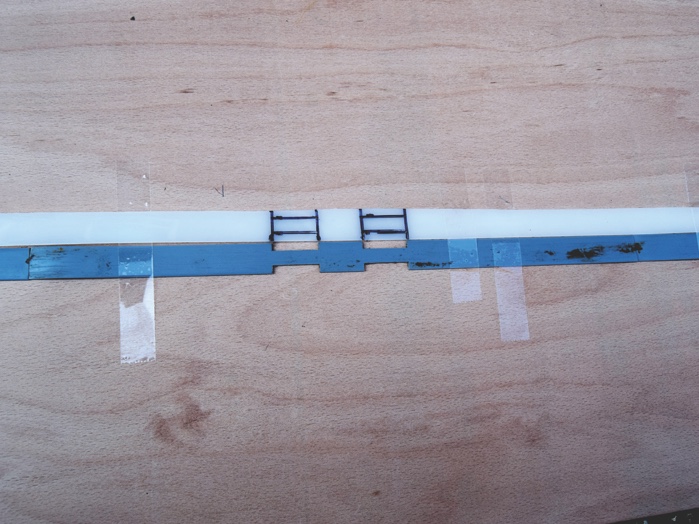

12. Reassemble PVC strip next to nylon strip, then mark aperture cutting points

13. Using a craft knife, carefully cut out the apertures as marked.

14. Using white spirit and a small brush, clean the inside of the guide channel.

15. Then apply PTFE spray to the inside of the track and allow it to dry.

16. Insert nylon strip into channel; clip in drive block and side catches. Replace stay-bracket and end-stop screw.

Certain older vans were fitted with windows made by a company called Birkholz, which has long since stopped manufacturing them - replacements are therefore difficult to come by