It’s quite amazing, what caravanners take for granted. For example, who’s ever given a thought to how all of those electrical items operate just when we want them to?

I recently visited BCA Group in West Yorkshire, where I was given an informative tour of its three constituent companies by Sales and Marketing Director, Wayne Boyd.

BCA Group is essentially three firms – BCA Leisure makes wiring harnesses, control panels and power distribution units (PDUs) for leisure vehicles, while BCA Motion deals with battery boxes and smaller-scale wiring harnesses for panel van conversion manufacturers.

The third company, Pennine Leisure Supplies (PLS), supplies dealerships and other outlets with accessories such as lamps, kettles, cable reels, water pumps, electrical sockets and switches, as well as easy-fit mains electric kits for van conversions.

BCA Leisure was founded in 1981 by Wim Batist. Before buying the company’s first premises (an old mill in the village of Mytholmroyd, a few miles from BCA’s current location), Wim would travel to the UK with his van and trailer loaded with touring accessories on a Monday morning, drive the length and breadth of the country throughout the week, selling his wares, then return home on Saturday to reload, ready for the following Monday.

Branching out

At the time, the best-seller was Smat towing mirrors, which he imported from Italy.

Wim’s father and brother ran a successful caravan dealership in the Netherlands, so you could definitely say caravanning was in the family’s blood.

On acquiring the old mill, as well as continuing to supply the accessories, Wim contacted some caravan brands, to see if he could supply them with 25m mains hook-up cables (caravan electrics were so much simpler back then!).

Once established in the UK, Wim was approached by one manufacturer about producing 230V wiring harnesses for dealer retrofit into caravans.

About 20 years ago, it was clear that new premises were needed – BCA had outgrown the old mill, and the industrial estate where they are now was in the process of development, so the mill was sold to help fund their new building.

Initially, PLS was also based at the industrial estate, but four years ago, owing to the need for larger premises, a new building was acquired, three miles away. The former PLS building is now rented by the well-known panel van converter WildAx.

BCA Group is still very much a family business. Wim Batist is the Chairman, his eldest son Harrison is in Business Development, and his youngest son William currently works

in the Technical Department.

Both Harrison and William are seen as the core of BCA’s succession plan, as the group, which employs 160 people, moves into the future.

BCA’s first wiring harnesses were made for Bailey, but now alongside them, control systems and harnesses are made for Coachman and Hymer UK, with Swift also buying some components from the group.

Cable and connectors

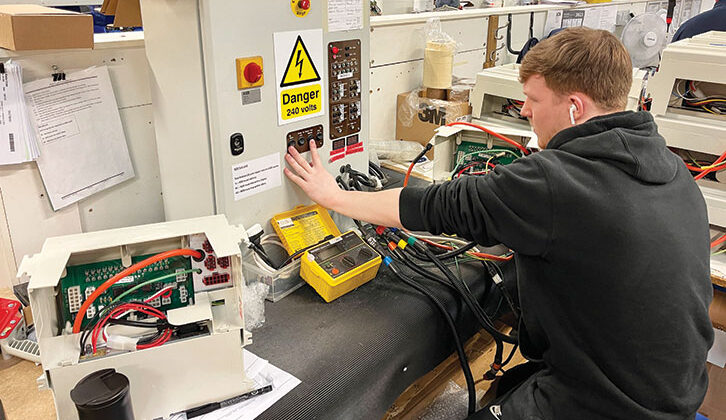

After outlining the history of the group, Wayne took me on a mind-boggling tour of BCA Leisure and BCA Motion.

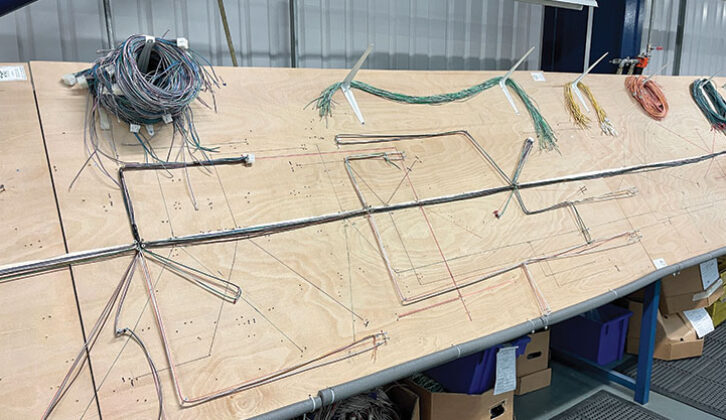

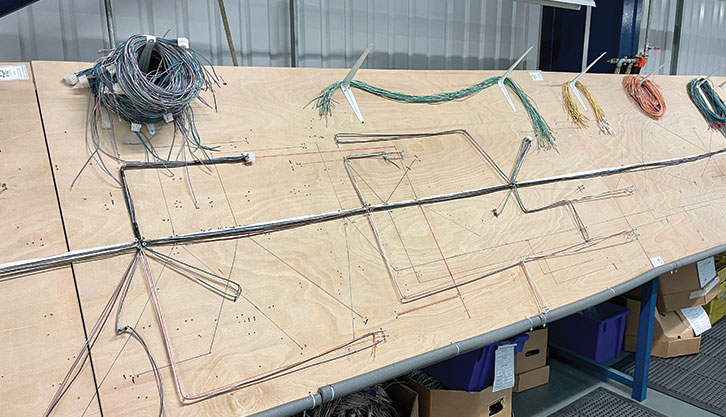

I say mind-boggling because I don’t think I’ve ever seen so much cabling, so many different connectors or such huge boards where the harnesses are made.

Much of this intricate work is done by hand, although there are some automated processes. Along the way, many tests and checks are carried out, and no completed harness or control unit will leave the facility until it has been thoroughly tested.

Weighty matters

Now that caravan wiring has become so complicated, there’s a weight implication.

BCA works closely with the van manufacturers to ensure that weight (which could easily exceed 25kg for a harness) is kept to a minimum, while still maintaining the most exacting quality standards.

In most cases, there’s a main floor harness with numerous ‘plug and play’ small harnesses connecting to that. BCA makes things as simple as possible for the manufacturers, for example by using a variety of plugs and sockets to ensure that the small harnesses only fit in the one required location, eliminating any potential errors.

As an example of just how complicated things have now become, consider this – one popular van’s floor harness has another 25 smaller harnesses that are attached to it. A 7.5m motorhome will quite easily house 600-700m of cabling!

Such is the relationship that BCA has with leisure vehicle manufacturers, if a brand plans to fit a new appliance, BCA is relied on to work out which thickness of cabling is required to cope with (and exceed) the potential load, and also to avoid any possible voltage drop.

Wayne also told me that in recent times, fridge harnesses have been quite challenging, because of the stop/start technology fitted to tow cars. The problem is, if the power cuts so many times, the fridge registers a fault and simply stops operating on 12V. Thankfully, BCA has overcome the problem.

When making a harness, the furthest point from the power supply is the starting point, likely to be a high-level brake light, and then it is worked back through the vehicle.

BCA Motion is where the harnesses and control systems for panel van conversions are assembled. Wayne’s knowledge of all the products was amazing. For example, he could look at a battery box and say which brand of vehicle it was destined for.

Our final destination was PLS, a huge warehouse and distribution centre, and a very impressive operation it is, too. Items are selected from shelves by a fork-lift truck, but much

of the work is semi-automated.

The fork-lift is programmed, so although there is a driver, it knows where it needs to go and where to select the item.

All I will say is that it’s a very long way up to the roof level!

With thanks to Wayne Boyd and Lewis Gresty (PLS) for showing me around.

After some more industry insight? Then check these out:

- We find out how LocknLevel’s popular system works.

- Great graphics can make a big difference to a caravan, as we found out at Creative Graphics International.

If you’ve enjoyed reading this article, why not get the latest news, reviews and features delivered direct to your door or inbox every month. Take advantage of our brilliant Practical Caravan magazine SUBSCRIBERS’ OFFER and SIGN UP TO OUR NEWSLETTER for regular weekly updates on all things caravan related.