The chances are that if you own a recently manufactured British caravan, the windows are likely to have been made by Dutch company Polyplastic. There will, of course, be some exceptions, but the majority will have come from the Rotterdam factory.

A subsidiary of Polyplastic is a company that you’re less likely to have heard of, Delta Glass, which manufactures all of the acrylic sheeting for those Polyplastic windows, and many more of the products that they make.

So how did it all get started? It actually began with a plane. Back in 1952, two friends, Wim Veeneman and Henk Kersten, were fascinated by the canopy of the Spitfire fighter plane.

They loved the way that it was formed from just one piece and was completely integral to the design of the aircraft.

In the same year, Poly-plastic (as it was named then) was founded as a company.

The following year, the firm started experimenting in the manufacture of acrylic sheeting, something they’d perfected by 1956, although this was at the rather leisurely rate of one sheet per week. Just compare that to the one sheet every 50 seconds produced today!

By 1978, it was clear that the company needed to expand, so a new plant for the manufacture of acrylic sheeting was built at Tholen, some 40 miles from the Poly-plastic plant.

This firm was initially called Kyo Glass, changing to Delta Glass in 2012, by which time the plant had expanded twice, in 1983 and again in 2005. By 1995, the Polyplastic Group

was in the hands of Wim’s son Jan Peter Veeneman, who took over from his father. Although Polyplastic was acquired by Lippert in January 2020, Jan Peter continues as CEO.

Acrylic windows

The UK was pretty slow off the mark when it came to using acrylic materials for caravan and motorhome windows – it wasn’t until the very late 1970s that it was first used, and then only on high-end vehicles. It wasn’t adopted universally until the early 1980s. However, Polyplastic had been producing acrylic windows for Continental markets since 1960.

Today, Polyplastic makes all kinds of products, mainly in the leisure sector, but also items such as fridge/freezer doors for supermarket units and the illuminated advertising units that you’re likely to see at airports and railway stations.

Of course, we’re aware of the caravan windows, but Polyplastic also manufactures rooflights, splashbacks and other decorative panels for both inside and outside caravans and motorhomes. These products are often design features of the models.

Clarity and strength

So why is acrylic (or to give it the correct title, polymethyl methacrylate) so suitable for leisure vehicles?

Compared to glass, it has excellent optical clarity and is very strong, which makes it much more resilient. It’s also very light and easy to mould into the shapes we see for windows and rooflights. It is flexible, and UV protected.

In addition, since 2014, Polyplastic windows have also had an anti-scratch coating.

Having seen uncoated and coated windows side by side in their laboratories, I can confirm that coated windows are more resistant to light scratches.

Another huge benefit, owing to its light weight, is that it is ideal for double-glazing, with all the advantages that entails.

Production process

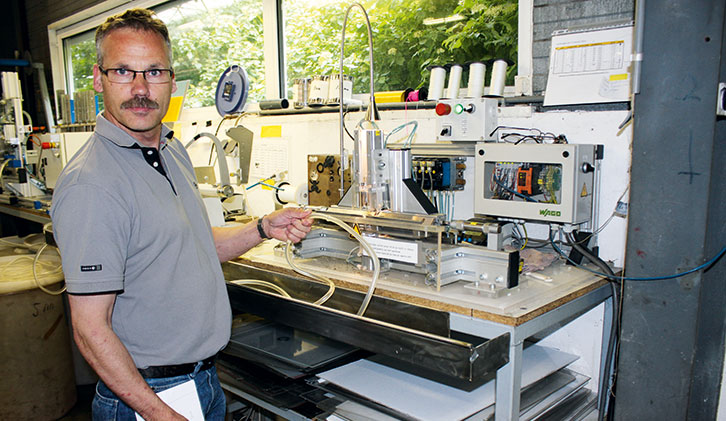

On a recent visit to the Delta Glass and Polyplastic factories, I followed their production process from beginning to end. At Delta Glass, thanks to their know-how in the production of acrylic sheets, staff designed and built the machinery.

This resulted in a far more efficient operation and reduced costs. The machines do exactly what they want them to.

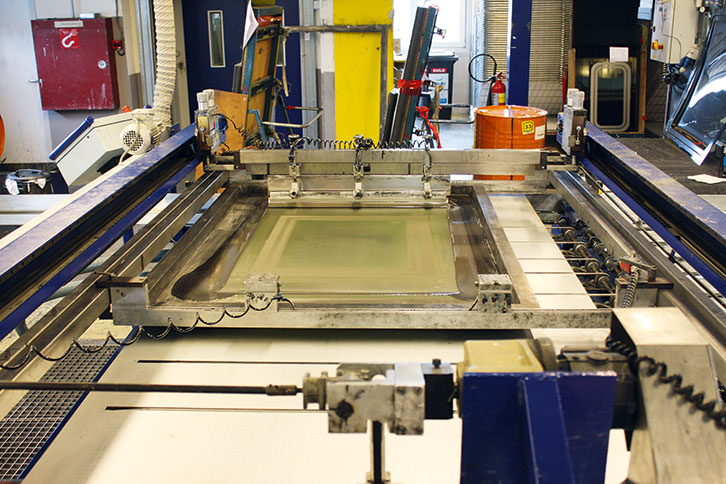

The process begins with the manufacture of a sealing bead from plastic pellets. This bead is then clamped between two large sheets of glass, set at the desired thickness apart; that is, 2mm, 5mm, 10mm and so on. Once the plates are securely clamped together, they’re sent on rollers to where they will be filled with a combination of the monomer (methyl methacrylate) and a catalyst.

Any colouring to form tinting will have been added to the monomer prior to this stage.

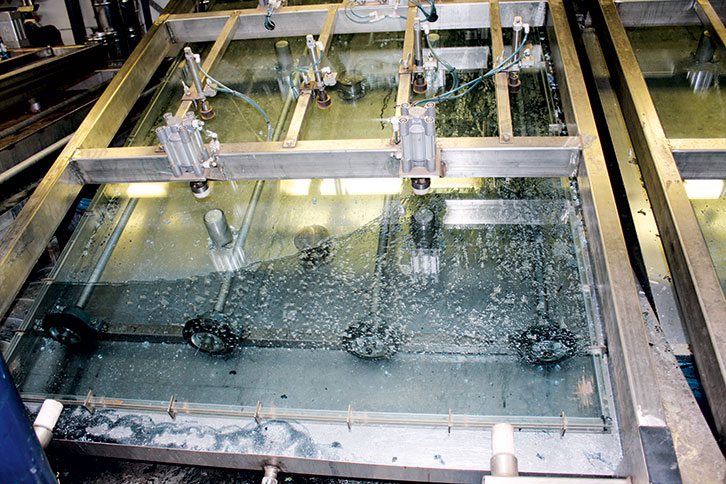

For filling, the glass plates are tilted at an angle and filled from the top. At the same time that the liquids are being fed into them, a series of soft hammers continually tap on

the surface to get rid of air bubbles. This is where Delta Glass’s expertise came in when designing and building their machinery, as they were aware that any bubbles might render an acrylic sheet unusable.

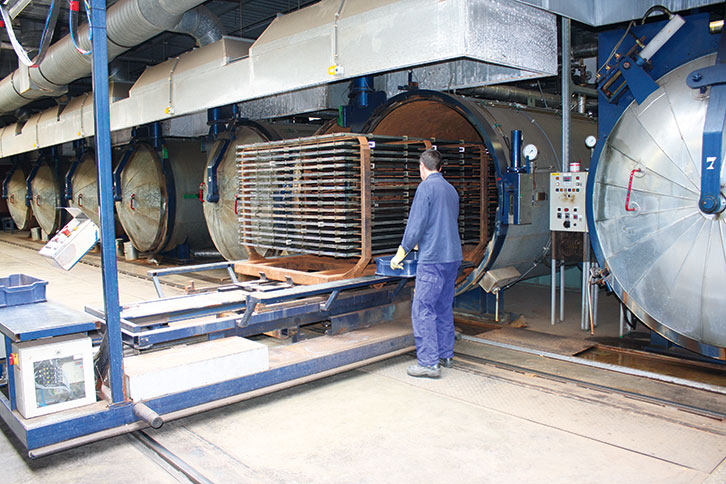

Once they are satisfied all the air bubbles have been removed, the glass plates containing the liquid acrylic are put into huge autoclaves to cure.

Each autoclave holds many such units. The sheets are cured for two hours in the autoclaves before being brought out and allowed to cool down.

There are in the region of 20 workers at Delta Glass and in total, approximately 1,500,000 pieces of acrylic sheet are produced per year.

The process at Delta

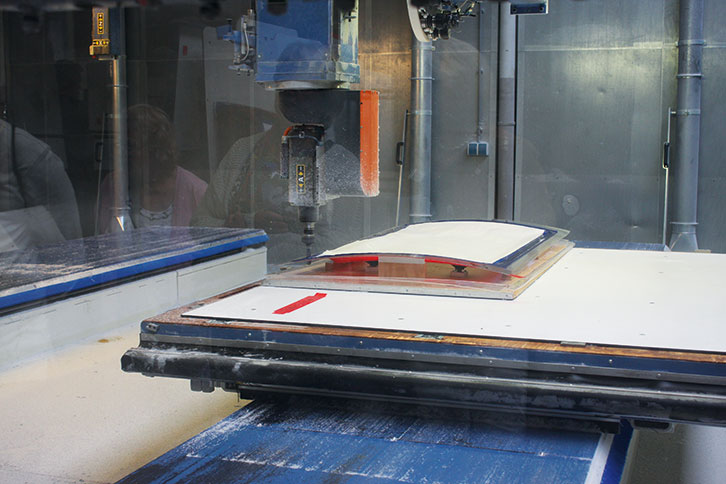

The process at Polyplastic

The acrylic sheets are then stored and palleted, ready to be transferred to Polyplastic.

Once the acrylic arrives at Polyplastic, it is machine cut (computerised, of course!) to the rough shape required.

Should any decorative screen print be required (for example, the black edging that we see framing many windows), it will be added at this point.

The flat piece of acrylic is then heated before being vacuum-moulded to the correct form and trimmed.

Double-glazed units, of course, require two sheets to be bonded together.

Once the windows have been made in their simplest form, they then have various catches and stays (and in some cases, whole window frames and rubbers) attached, before being prepared for shipping.

That’s just a brief insight into this complex process, but it was certainly fascinating to witness.

If you enjoyed this, why not take a look at these:

- We go behind the scenes at Pro-tec Covers

- We find out about the installation process of Alde Flow

- We take a look at LocknLevel, to find out how the popular system works

If you’ve enjoyed reading this article, why not get the latest news, reviews and features delivered direct to your door or inbox every month. Take advantage of our brilliant Practical Caravan magazine SUBSCRIBERS’ OFFER and SIGN UP TO OUR NEWSLETTER for regular weekly updates on all things caravan related.