Caravanners really are an inventive lot. Whether it’s because we spend hours relaxing in our vans and have the time to think about how something could make life easier, I don’t know. But what is a fact is that much of the touring kit we take for granted has come from the minds of other caravanners.

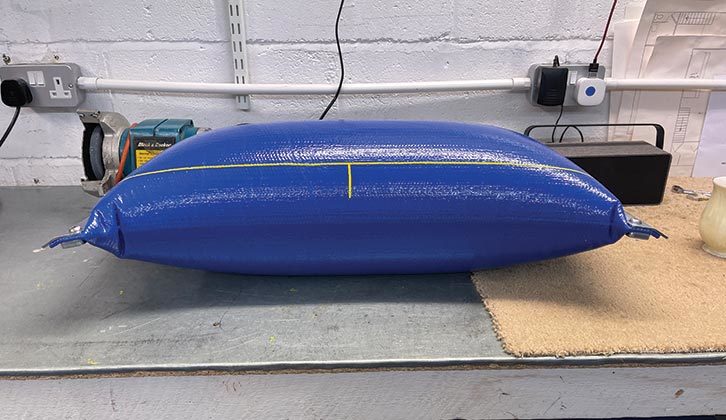

One such invention is the inflatable LocknLevel caravan levelling system. Like so many things, its basic principle is so simple, yet it’s very clever.

I remember years ago seeing recovery companies righting overturned lorries using little more than steadying ropes and big inflatable airbags. Surely, if these things will lift 40-tonne lorries, two tonnes of caravan should be easy? These must have been the thoughts of LocknLevel founder Derek Ibbotson in 2012.

I recently visited the firm to find out more about its history and how LocknLevel developed.

Keen caravanners

Derek and his wife Jacky are keen lifelong caravanners, and in 2012, Derek (together with his original business partner, who has now retired) decided they’d had enough of the rigmarole of levelling their vans using ramps, and the difficulty of putting on wheel locks when the wheel was on a levelling ramp – that is, the caravan was level, but the wheel was in the wrong place for the lock. We’ve all been there.

Back then, Derek was in the plumbing trade and his business partner was in the automotive industry. He was also fortunate enough to have what he calls his “hobby room” at home.

One day, quite out of the blue, Derek’s partner asked, “I wonder if we could use air to level a caravan?” The seed was sown.

They got hold of an airbag from a car breaker, and their wives sewed it back together, inserting an inner tube. Then the experimenting began.

Derek said, “We blew it up and it lifted our caravan – just before it burst with an almighty bang. It was a Sunday morning, and several of our neighbours came out to see what the bang was and what we were up to. They all left laughing! We played around with it for a few weeks until we finally got it to work. We suddenly realised we were onto something, so LocknLevel was registered.”

For the first three months, production of the LocknLevel system (including manufacture of the brass Schrader valves) was in Derek’s hobby room.

Very quickly, however, it became obvious that producing the LocknLevel units on a bigger scale would require industrial premises. Not long after that, production started in a location just across the road from where the firm is based today.

LocknLevel was perfected very quickly and has remained pretty much unchanged since then. “As caravanners ourselves, we recognised the problem of levelling in the first place, but once it was perfected, we had remarkably few issues with the units,” Derek said.

To date, more than 15,000 LocknLevel systems have been sold, with units going as far afield as Australia. Derek told me, “I remember being chuffed to bits when we’d managed to sell our first 10!”

Sourcing parts

The reinforced tubing for the units comes on 100m rolls, which weigh 250kg each. “We tried a number of suppliers for the tubing. Although what we use is a bit more expensive, it’s proved to be by far the best for our purposes,” he explained.

“The metal parts are sourced locally, well, foreign parts really – Milton Keynes,” Derek joked. Obviously some local rivalry going on there!

“Sourcing those components, I took an example of what we wanted to a family-run company, and asked them if they thought they could make something like that. To which their boss replied, “I think so.” When we told him how many we wanted, he must have thought all his Christmases had come at once,” said Derek.

LocknLevel advertises its products (including in Practical Caravan), which does generate sales, but many units are sold by word of mouth and online.

“Caravanners are a very chatty bunch,” Derek said. The company also exhibits at the February and October NEC shows, which prove very fruitful, he added; especially the October one.

Single and twin

The single-axle version of LocknLevel will lift a 1500kg caravan four inches (10cm) at a pressure of only 20 psi, using a car tyre pump.

A maximum pressure of 30 psi is recommended, which gives a six-inch (15cm) lift, and is more than most levelling ramps.

The twin-axle version works at even lower pressure. Derek told me that they’d once had some fun by asking people to guess what the pressure was on a unit that lifted a twin-axle caravan by six inches.

There were lots of really high guesses, but the actual answer was only 14 psi! There is no weight limit on either of the units, although the 30 psi cap must never be exceeded.

I also asked Derek whether temperature variations affected the system’s function. He said they’d done a fair bit of testing on this aspect and found that, although the pressures dropped a bit when it was cooler, there was no reduction in the lift, which remained stable.

Since Derek’s original partner retired, son Andrew has bought into the business, so these days, it really is a family affair.

Jacky looks after the admin, and Andrew has ideas on how to take the company forward, particularly concerning the marketing strategy.

As always, Derek loves doing the practical stuff. There are currently three employees as well as electrical whizz and family friend, Trevor, who lends a hand when he can.

Looking to the future, they are in the process of obtaining the industrial unit next door, to double the size of the operation, particularly in storage space.

There’s also another exciting innovation in the pipeline, but Derek was understandably guarded about that. I’m looking forward to seeing it, and testing LocknLevel on our own caravan soon.

LocknLevel, Acacia Close, Leighton Buzzard LU7 4QE, 01525 375 271, http://locknlevel.co.uk

If you enjoyed reading this, why not take a look at these:

- We go behind the scenes at Alde Flow, finding out about the installation process

- We find out about Pro-tec Covers, finding out about how a cover can keep your tourer clean and protect it from damage on the road

- Nigel Hutson takes a trip to Paintseal Direct to find out about a specialised finish

Future Publishing Limited, the publisher of Practical Caravan, provides the information in this article in good faith and makes no representation as to its completeness or accuracy. Individuals carrying out the instructions do so at their own risk and must exercise their independent judgement in determining the appropriateness of the advice to their circumstances. Individuals should take appropriate safety precautions and be aware of the risk of electrocution when dealing with electrical products. To the fullest extent permitted by law, neither Future nor its employees or agents shall have any liability in connection with the use of this information. You should check that any van warranty will not be affected before proceeding with DIY projects.

If you’ve enjoyed reading this article, why not get the latest news, reviews and features delivered direct to your door or inbox every month. Take advantage of our brilliant Practical Caravan magazine SUBSCRIBERS’ OFFER and SIGN UP TO OUR NEWSLETTER for regular weekly updates on all things caravan related.